Best Conference Table Materials for Pune’s Climate

You’ve been there. You invest in a beautiful, brand-new conference table. It’s the centerpiece of your Pune office, where deals are closed and big ideas are born. It looks fantastic for the first year.

Then, after its second monsoon, you notice the laminate corner is starting to bubble and peel. By the following summer, a thin, hairline crack appears on the wood surface. Or perhaps the "stainless" metal legs are showing small, spider-web-like rust spots near the floor.

Here in Pune, your office furniture is fighting a two-front war against the climate. And as modular furniture manufacturers based right here , we see the casualties every day.

The problem isn't your cleaning crew. The problem is that you were sold a piece of furniture that wasn't engineered to survive what we call the "Pune Whipsaw Effect."

This isn't just another "wood vs. metal" article. This is a procurement manager's guide to the technical specifications you must look for to avoid a costly mistake. We're going to share the manufacturing-level details that most suppliers won't tell you.

The "Whipsaw Effect": Pune's Real Threat to Your Furniture

The real enemy of your conference table isn't just "rain" or "sun." It's the extreme, back-to-back fluctuation between two opposing climates. This "whipsaw" effect of expansion and contraction is what destroys furniture from the inside out.

The Monsoon (June-Sept) - The "Swelling" Season

When we say "monsoon," people think of rain. You should think of humidity.

Pune's climate data is startling. While the average humidity is around 69%, it skyrockets to a suffocating 92% in peak monsoon months. This isn't just an outdoor problem; studies show indoor relative humidity (RH) in India can hit 98% during this time.

Here’s what that moisture does to your table:

- Wood: Wood is hygroscopic, meaning it acts like a sponge. It absorbs all this airborne moisture, causing the fibers to swell, warp, and deform.

- Adhesives: The moisture attacks the glues used in your furniture. This is why laminates and veneers "delaminate" and peel away from their core.

- Metal: The combination of constant moisture and oxygen is the perfect recipe for corrosion, accelerating rust on any vulnerable metal component.

The Summer (March-May) - The "Shrinking" Season

Just a few months later, the climate "whipsaws" to the other extreme. The hot, dry summer causes indoor humidity to plummet, with relative humidity dropping as low as 20%.

Now, that same piece of furniture faces the opposite problem. All the moisture it soaked up during the monsoon is rapidly pulled out of the material.

- Wood: The wood fibers shrink, dry out, and become brittle. This rapid contraction is what causes wood to crack, split, and check.

- Joints: This cycle of swelling (monsoon) and shrinking (summer) puts immense stress on every joint, glue-line, and fastener, weakening the table's entire structural integrity over time.

Why Your Air-Conditioned Office Isn't a "Safe Zone"

This is the most common objection we hear: "But my office is air-conditioned."

While ACs help, they are a dangerously incomplete solution. An AC's primary job is to cool the air, not necessarily to dehumidify it.

In fact, a common problem in commercial build-outs is an oversized AC unit. According to HVAC experts, a unit that is too large cools the air so fast that it doesn't have time to remove the water vapor. This creates a "cold and clammy" feeling. The office feels cool, but the relative humidity is still high, allowing mold to grow and moisture to attack your furniture.

The takeaway: You cannot rely on an AC unit to protect your investment. The furniture itself must be built to resist moisture from its very core.

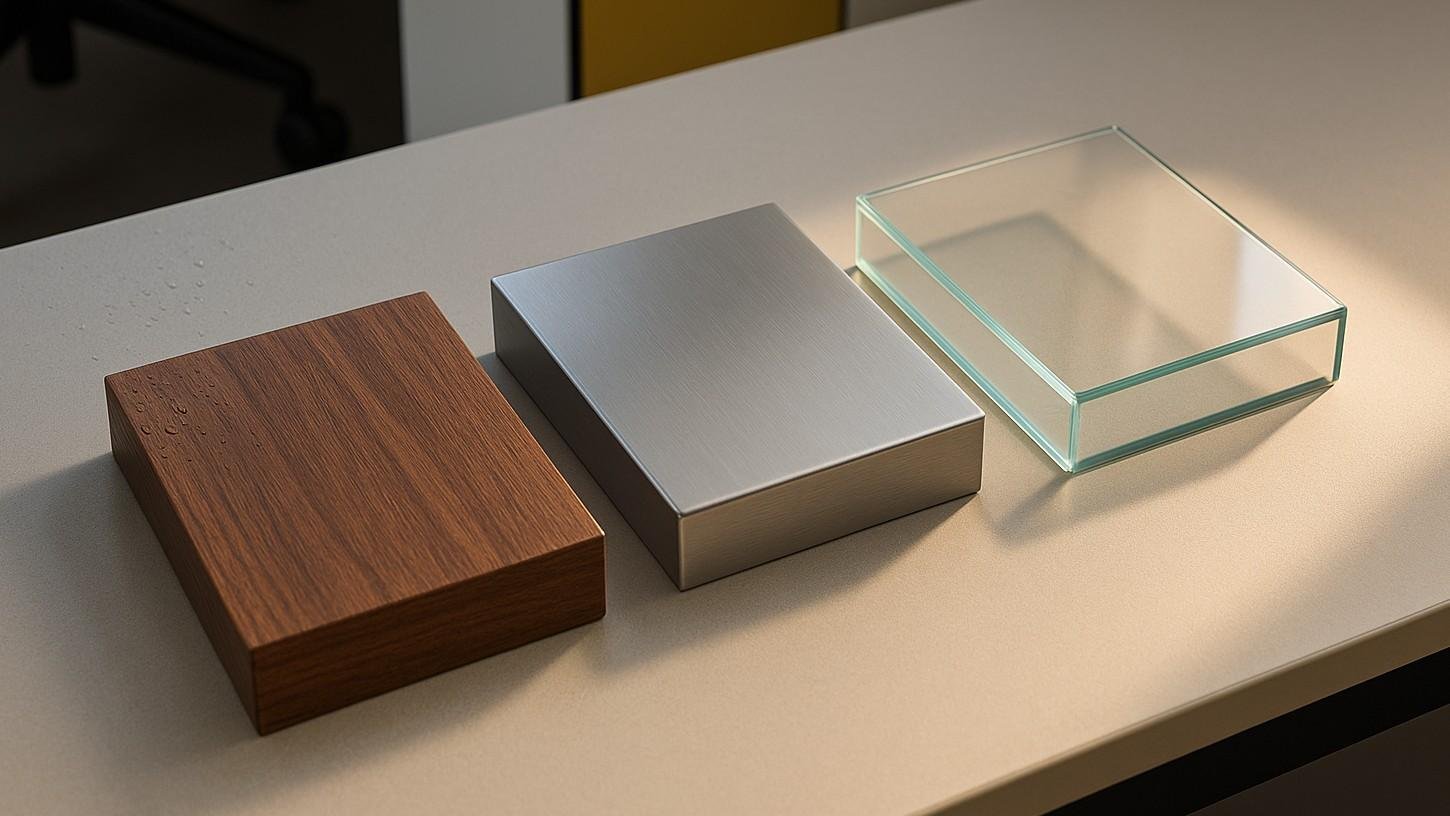

Material Deep Dive 1: The Truth About "Wood" Conference Tables

As manufacturers, we can tell you that "wood" is the most dangerously vague term in our industry. A "wood" table's survival in Pune has nothing to do with its wood-grain pattern and everything to do with what's underneath.

The High-Risk Choices: Materials That Will Likely Fail

- Solid Wood: This is the biggest trap. It looks and feels premium, but it's the most susceptible to the Whipsaw Effect. Because it's a natural, solid material, it will expand, warp, and crack more dramatically than any other option. It's a beautiful, high-risk, and high-maintenance choice not recommended for a Pune office.

- Standard MDF (Medium-Density Fibreboard) & Particleboard: This is the "sponge" of the furniture world. Standard MDF is "less moisture-resistant and can swell or degrade when exposed to water". In humid regions, it will soak up the monsoon moisture, bubble, and disintegrate. Avoid this at all costs.

The "Pune-Proof" Wood Table: A System of Core + Skin

A wood table that can survive here is an engineered system. Its strength comes from two parts: its internal Core and its external Skin.

The Core Material: A "Good, Better, Best" Hierarchy

This is the number one secret you need to know. The difference between a table that lasts 18 months and one that lasts 10 years is the adhesive used in its plywood core.

- "Good" (But Risky): MR Grade Plywood (IS:303)

- MR stands for "Moisture Resistant". This is the trap. Most people hear "moisture resistant" and think it's fine for Pune. It is not. MR Grade is not waterproof. It uses a "Urea-formaldehyde" resin and is only intended for dry areas like bedrooms or living rooms. A Pune monsoon is far beyond its design capabilities.

- "Better" (The Smart Baseline): BWR Grade Plywood

- BWR stands for "Boiling Water Resistant". This is the smart, cost-effective baseline. The critical difference is the adhesive: it's made with "phenol formaldehyde resin" , which has "remarkable waterproofing properties". This plywood is specifically designed for high-moisture zones like kitchens and bathrooms —which makes it a perfect match for a Pune office in August.

- "Best" (The Manufacturer's Choice): HDF-HMR (High-Density High Moisture-Resistance)

- This is the top-tier core material. HDF-HMR is a "High-Density Fibreboard" that is denser, stronger, and far more water-resistant than MDF. It's engineered by pressing wood fibers with special resins to create a robust, high-density board. As one 2024 analysis puts it, a kitchen made with HDF-HMR "remains intact" after multiple monsoons, whereas an MDF kitchen will fail.

The Skin: Sealing the Deal with the Right Laminate

Once you have a strong core, it must be sealed.

- The Risk (Veneer): A wood veneer is a very thin slice of real wood. While beautiful, it's still just wood. It can be vulnerable to the same moisture that causes peeling.

- The Solution (Laminate): Laminate is the clear winner for durability. But again, not all laminates are equal. You need HPL (High-Pressure Laminate). HPL is fused at high pressure and is "superior" for its "outstanding impact, abrasion, and moisture resistance". It's much tougher than the thinner, less-durable LPL (Low-Pressure Laminate).

Our Verdict on Wood:

A "wood" table is an excellent choice only if it is specified as a sealed system. This is the same logic you'd apply to a high-use executive chair; you'd check the foam density and mechanism, not just the fabric. For your table, demand a core of HDF-HMR or BWR-Grade Plywood and a skin of High-Pressure Laminate (HPL).

Material Deep Dive 2: The "Metal" Trap (And How to Avoid Rust)

Metal seems like the obvious durable choice, but it has a critical, hidden vulnerability: corrosion.

Why That "Durable" Powder-Coated Table Will Fail

Most "durable" metal tables are just mild steel with a powder-coated finish. This finish is essentially a layer of paint "baked" onto the metal. It looks great, but it's only a seal.

Here's the failure scenario:

- A chair leg, vacuum cleaner, or briefcase scrapes the table leg, creating a tiny, imperceptible scratch in the powder coat.

- During the monsoon, humidity seeps under that seal.

- The mild steel underneath the coating begins to rust, spreading unseen.

- This corrosion "bubbles" the paint from below, causing the "durable" finish to flake and peel off, revealing a rusted, weakened leg.

The Contrarian Angle: The "Stainless Steel" Lie

"Okay," you say, "I'll just buy stainless steel."

Be careful. This is one of the most common traps in B2B procurement. Most experts agree that not all stainless steel is created equal. The grade is the only thing that matters.

- The Trap (SS 202): This is a cheaper, low-nickel, high-manganese grade of stainless steel. It looks identical to the good stuff. However, a 2025 report confirms SS 202 is "More likely to rust in moist... areas" and "tends to corrode faster" in humid climates. It is the wrong choice for Pune.

- The Solution (SS 304): This is the correct specification. SS 304 has a high-nickel and high-chromium content. This alloy gives it "Excellent" corrosion resistance, making it the standard for "high-humidity" and "coastal regions".

Beyond Coatings: PVD vs. Powder-Coating

If you're buying a coated metal table, you have two main options.

- Good (Baseline): Powder Coating. As we've seen, it's a decent seal but carries a high risk of failure if the seal is ever breached.

- Best (The Premium Fix): PVD (Physical Vapor Deposition). This is a high-tech process that's fundamentally different from paint. PVD bonds a thin layer of metal at a molecular level to the base. It's not a layer on top; it's part of the metal.

- PVD is "superior" to powder-coating in durability and corrosion resistance.

- It is "inherently waterproof" with a seamless finish.

- Most telling, PVD is the "tried and tested approach" for luxury hardware in "corrosive coastal environments" where powder-coats are known to fail.

Our Verdict on Metal:

A metal table is a fantastic, modern choice, but you must be specific. Demand either Solid SS 304 Stainless Steel for the frame and legs, or a metal base finished with a PVD coating.

Material Deep Dive 3: Glass (It's Not About the Glass, It's About the Frame)

Glass tables are sleek, modern, and popular. And when it comes to climate, the glass itself is almost a non-issue.

Why the Glass Top is a "Climate-Proof" Material

- Moisture-Proof: The glass surface is 100% "water and humidity proof". It cannot swell, warp, or rust.

- Temperature-Proof: A common worry is, "Will the glass crack from the temperature swings?" The answer is no. Modern conference tables use tempered safety glass. Tempered glass is engineered to withstand temperature changes of up to 150°C , which is 3-4 times more resilient than regular glass. Pune's seasonal shift from a hot summer to a cool monsoon is well within its tolerance.

But a glass table will still fail in Pune. Why?

Because you aren't buying a "glass" table. You are purchasing a frame that happens to have a glass top.

The Real Failure Points of a Glass Table

- Failure Point 1 (The Frame): This is the critical weakness. That beautiful glass top is resting on a frame, and that frame is almost always made of... wood or metal. If the manufacturer used cheap MR Grade plywood or SS 202 steel for the frame, the frame will fail. It will swell or rust , making the entire table wobbly, unstable, and unsafe, even while the glass top looks perfectly pristine.

- Failure Point 2 (The Adhesives): On some designs, adhesives are used to bond the glass to the base. A study on furniture durability found that prolonged UV exposure from intense summer sun can cause these adhesives to "yellow or discolor over time" , ruining the table's clean aesthetic.

- Failure Point 3 (The "Nuisance Factor"): This isn't a failure, but a significant annoyance. During the high-humidity monsoon, the cool glass surface is a magnet for condensation, leaving constant "unsightly watermarks" that require endless cleaning.

Our Verdict on Glass:

A glass table is a great, durable choice for Pune if and only if you verify its foundation. It must have a tempered glass top paired with a "Pune-Proof" frame made of SS 304 Stainless Steel or PVD-coated metal.

The Verdict: A Procurement Manager's Cheat Sheet

You don't need to guess. Here is a simple matrix to guide your next purchase.

| Material System | Monsoon (Humidity) Risk | Summer (Dryness) Risk | The "Pune-Proof" Specification |

| Solid Wood | Very High (Swells, Warps) | High (Cracks, Splits) | Not Recommended. |

| MDF / Particleboard | Extreme (Swells, Disintegrates) | Low | AVOID AT ALL COSTS. |

| Engineered Wood | Low | Low | HDF-HMR or BWR-Grade Plywood Core + HPL Finish. |

| Powder-Coated Mild Steel | High (Rusts under breached seal) | Low | Risky. Fails if scratched. |

| SS 202 Stainless Steel | High (Will rust) | Low | Not Recommended (Common trap). |

| Metal (Preferred) | Very Low | Low | Solid SS 304 Stainless Steel or PVD-Coated Metal. |

| Glass Table | Low (Nuisance) | Low | Tempered Glass Top + SS 304/PVD Frame. |

The Takeaway: Stop Buying Furniture, Start Investing in Manufacturing Specs

Your conference room is a long-term asset. Don't let it become a short-term liability.

Many furniture suppliers in Pune compete on looks or price. When their products fail, their advice is focused on maintenance—they tell you to buy dehumidifiers, apply car wax to your metal furniture, and re-polish your wood. This puts the burden of durability on you.

We believe durability should be built-in from day one.

As a Pune-based manufacturer , we compete in engineering. We're the ones who obsess over the difference between BWR and MR grade plywood or SS 304 and SS 202 steel so you don't have to. We engineer our modular office furniture—from conference tables to workstations—to survive our specific local climate.

Before you buy your next piece of office furniture, ask your supplier:

- "Is the core HDF-HMR or BWR-grade plywood?"

- "Is that stainless steel SS 304 or SS 202?"

- "Is that finish PVD or powder-coating?"

If they can't answer, talk to someone who can.

Your conference table is an investment. Let's make sure it's a lasting one. Contact the Office Mantra team today for a consultation on the exact materials and specifications that will survive and thrive in your Pune office.